Electrical safety is a critical component of any work environment, playing a vital role in preventing accidents, ensuring regulatory compliance, and protecting both personnel and property. Our Electric Safety Training programs are meticulously designed to equip employees, technicians, and facility managers with the knowledge and skills required to recognize hazards, apply safe work practices, and respond effectively to emergencies involving electrical systems.

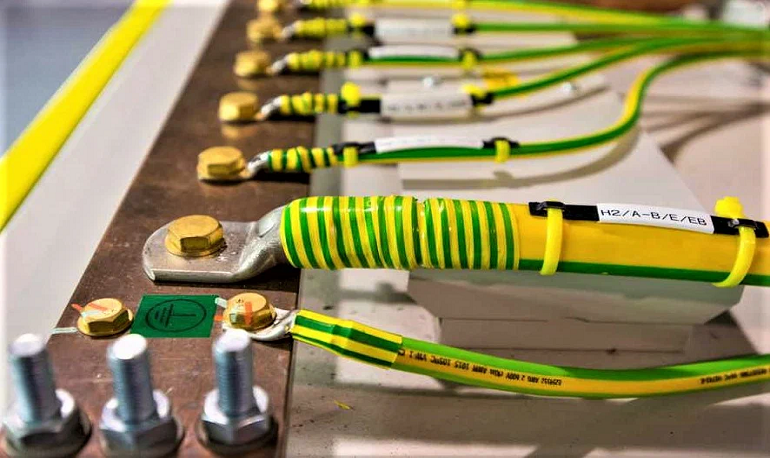

Proper earthing, also known as grounding, is a fundamental aspect of electrical safety and system reliability. It ensures fault currents have a direct path to the ground, reduces the risk of electric shock, and protects equipment from voltage surges. Our Earthing Electrical Training is designed to educate participants on the principles, practices, and regulatory requirements of grounding systems in both residential and industrial settings.

Accurate load calculation is essential for designing safe and efficient electrical systems. It ensures that wiring, protection devices, and power sources are appropriately sized to handle expected electrical demand without overloading circuits or wasting resources. Our Load Calculation Training program provides practical knowledge and technical skills required to evaluate, plan, and manage electrical loads in various environments, from residential buildings to complex industrial setups.

Power factor improvement plays a critical role in enhancing electrical efficiency, reducing energy costs, and minimizing losses in power distribution systems. Our Power Factor Improvement Training equips participants with a deep understanding of reactive power, system inefficiencies, and corrective methods to optimize the power factor in residential, commercial, and industrial environments.

Preventive maintenance is essential for ensuring the long-term reliability, safety, and efficiency of electrical systems. By identifying potential issues before they become costly failures, organizations can minimize downtime, extend equipment lifespan, and improve overall operational performance. Our Preventive Maintenance Training prepares technicians, electricians, and facility managers to implement proactive maintenance strategies tailored to a wide range of electrical systems and environments.

Slogans are powerful tools in electrical safety training — they reinforce critical safety messages, promote awareness, and create a culture of vigilance among workers. Short, memorable phrases can significantly impact how safety practices are remembered and applied in day-to-day electrical operations. Our Electrical Safety Slogan Module is designed to support training programs by embedding key safety principles through engaging and effective messaging.

Energy efficiency is not just about reducing costs — it's about building sustainable practices that benefit both the environment and long-term operational performance. Our Energy Saving Training is designed to empower technicians, facility managers, and energy coordinators with the knowledge and tools needed to identify inefficiencies, implement energy-saving strategies, and comply with green building and energy management standards.

Electrical panels are the heart of any power distribution system, and their safe operation is critical to protecting both personnel and equipment. Improper access, overloaded circuits, and poor maintenance can lead to arc flash incidents, equipment failure, or even fire. Our Electrical Panel Safety Training is designed to ensure that technicians, maintenance staff, and supervisors understand how to safely interact with and maintain electrical panels in compliance with industry standards.